Category: current injection anode

Anode MMO

Zinc anodes are used to protect structures submerged in fresh or salt water...

Current injection anode

MMO anodes

(Mixed Metal Oxide Anode)

Bernagdas MMO anodes consist of two parts: base metal and coating.

Anodes (Mixed Metal Oxide Anode)

MMO anodes

(Mixed Metal Oxide Anode)

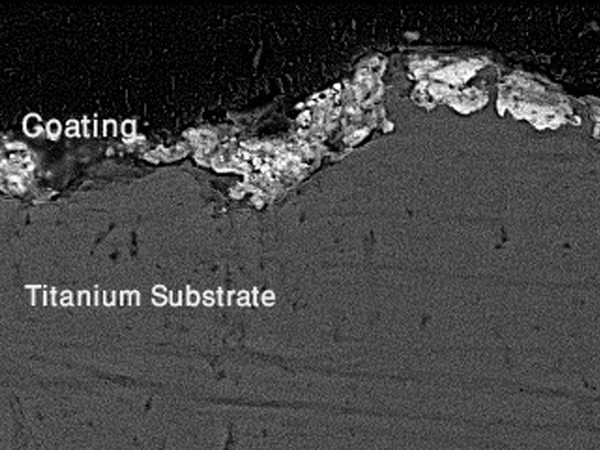

Bernagdaz MMO anodes consist of two parts, the base metal and the coating. Titanium is used as the base metal because this metal has the required properties to receive the coating to deal with aggressive chemical environments and is suitable for current transmission. Other advantages of titanium include its use in various forms such as tube, strip, wire, net and plate.

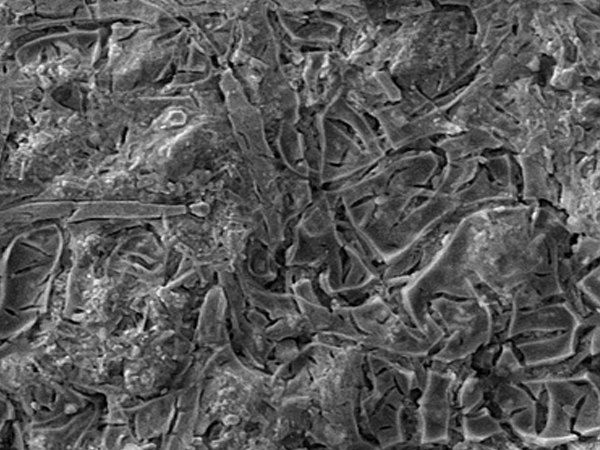

The coating of MMO anodes is very thin (a few microns) and can be applied to the base metal in different ways. Depending on the type of application, this coating can be a combination of two or more metal oxides, including iridium, tantalum, ruthenium and titanium oxides.

By applying this coating as an activating agent, the additional potential for the release of chlorine and anode oxygen is significantly reduced because the catalytic coating of the MMO anode creates a small resistance for the anode, which leads to a lower consumption rate considering the length. It becomes its life.

MMO anodes have a very low consumption rate of less than mg/A.Year 1 depending on the environmental conditions and application.

The maximum output current density and lifetime of MMO anodes in different environmental conditions are as follows:

Heat treatment furnace for MMO anodes

In general, MMO anodes have the following advantages:

- Easy to use

- The possibility of producing anodes with different shapes

- Easy portability

- Low weight

- High output current

- Long lifetime at very high current densities

- Dimensional stability

- Possibility of re-covering

- Reliability

These anodes are used in current injection cathodic protection systems to deal with the corrosion of metal base structures. The most common applications of these anodes are in the maintenance of bridges, marine structures, marine platforms, the bottom of storage tanks, pipelines buried in soil or immersed in water, and concrete structures.

An example of MMO cathode protection anodes

The common forms of MMO anodes for cathodic protection are as follows:

- Tubular MMO anodes

Tubular MMO anodes are used for cathodic protection of metal structures buried in soil (directly or with carbon backing) or submerged in water.

An example of anodized MMO anodes

The titanium substrate of these anodes is selected based on the requirements of the ASTM B338 Grade 1 or 2 standard. The output current and lifetime of tubular MMO anodes according to the size and different environmental conditions are as follows:

| Environmental conditions | anode size (Length x Diameter) | Output Current (A) | life span (Year) |

| Soil, coke and fresh water | (in 48 × in 4/3) mm1220 × mm 19 | 7 | 25 |

| (in 7/19 × in 1) mm500 × mm 25 | 4 | 25 | |

| (in 4/39 × in 1) mm1000 × mm 25 | 8 | 25 | |

| (in 48 × in 1) mm1220 × mm 25 | 3.5 | 25 | |

| (in 60 × in 1) mm1500 × mm 25 | 4.5 | 25 | |

| (in 48 × in 25/1) mm1220 × mm 75/31 | 12 | 25 | |

| sea water | (in 48 × in 4/3) mm1220 × mm 19 | 45 | 25 |

| (in 7/19 × in 1) mm500 × mm 25 | 25 | 25 | |

| (in 4/39 × in 1) mm1000 × mm 25 | 50 | 25 | |

| (in 48 × in 25/1) mm1220 × mm 75/31 | 75 | 25 |

- Strip MMO anodes

Strip MMO anodes are used for cathodic protection of pipelines and tanks. The titanium base of these anodes is selected based on the requirements of the ASTM B265 Grade 1 standard.

An example of MMO anodes of Bernagdaz strip

The dimensions and weight of strip MMO anodes and their maximum current density and lifetime are shown in the following tables:

| wide | (in 0.25) mm6.35 |

| thickness | (in 0.025) mm 0.635 |

| Standard coil length | m 100 |

| Standard coil weight | kg 1.5 |

| The surface area of the tape | m2 Per/m0.014 |

| Environmental conditions | Output Current (mA/m) | Approximate lifespan (Year) |

| fine sand | 42 | 50 |

| Concrete | 1.5 | 100 |

- Grid strip MMO anodes

Mesh tape MMO anodes are used for cathodic protection of concrete structures. The titanium substrate of these anodes is selected based on the requirements of the ASTM B265 Grade 1 standard. The output current and lifetime of MMO anodes in concrete according to their width are shown in the following table:

wide (mm) | Output Current (mA/m) | Approximate lifespan (Year) |

| 10 | 2.75 | 75 |

| 13 | 3.7 | 50 |

| 3.5 | 100 | |

| 15 | 4.1 | 50 |

| 3.9 | 75 | |

| 20 | 5.6 | 50 |

| 4.9 | 75 | |

| 4.7 | 100 |

- Wire MMO anodes

Wire MMO anodes are used for cathodic protection of metal structures buried in the soil, such as pipelines and tank bottoms.

An example of wire MMO anodes Bornagodaz

The titanium base of these anodes is selected based on the requirements of the ASTM B863 Grade 1 or 2 standard. The output current of wire MMO anodes according to their size is as follows:

wire diameter (mm) | Output Current (A/m) | ||

| sea water | fresh water | Carbon backfill | |

| 1.5 | 3 | 0.5 | 0.5 |

| 2 | 4 | 0.66 | 0.66 |

| 3 | 6 | 1 | 1 |

- Mesh MMO anodes

Mesh MMO anodes are usually used for cathodic protection of concrete structures.

- Custom MMO anodes

Bernagdaz company has the ability to produce all kinds of MMO anodes according to customers’ orders, including disk, probe, rod, belt, mesh tube, etc.

An example of a probe MMO anode Bornagodaz

Bernagdaz MMO anodes consist of two parts, the base metal and the coating. Titanium is used as the base metal because this metal has the required properties to receive the coating to deal with aggressive chemical environments and is suitable for current transmission. Other advantages of titanium include its use in various forms such as tube, strip, wire, net and plate.

The coating of MMO anodes is very thin (a few microns) and can be applied to the base metal in different ways. Depending on the type of application, this coating can be a combination of two or more metal oxides, including iridium, tantalum, ruthenium and titanium oxides.

By applying this coating as an activating agent, the additional potential for the release of chlorine and anode oxygen is significantly reduced because the catalytic coating of the MMO anode creates a small resistance for the anode, which leads to a lower consumption rate considering the length. It becomes its life.

MMO anodes have a very low consumption rate of less than mg/A.Year 1 depending on the environmental conditions and application.

The maximum output current density and lifetime of MMO anodes in different environmental conditions are as follows:

MMO technical documents Bornagodaz

Sample datasheet of tubular MMO anode

Sample data sheet of tubular MMO anode (chain type)

Sample datasheet and MMO ribbon (ribbon)

MMO anode production approval from the continental shelf oil company (IOOC)

Approval of MMO anode production from Pars Oil and Gas Company (POGC)